Equipment of Mikrostrukturlabor (MSL)

The Mikrostrukturlabor (MSL) offers a wide array of fabrication and characterization tools as well as established process chains for complex micro- and nanostructures made form a wide array of materials. We are happy to assist with services as well as granting lab access for internal and external users who peruse more complex tasks requiring significant lab time.

If you are interested in any of our tools, processes, or similar, please do not hesitate contacting us

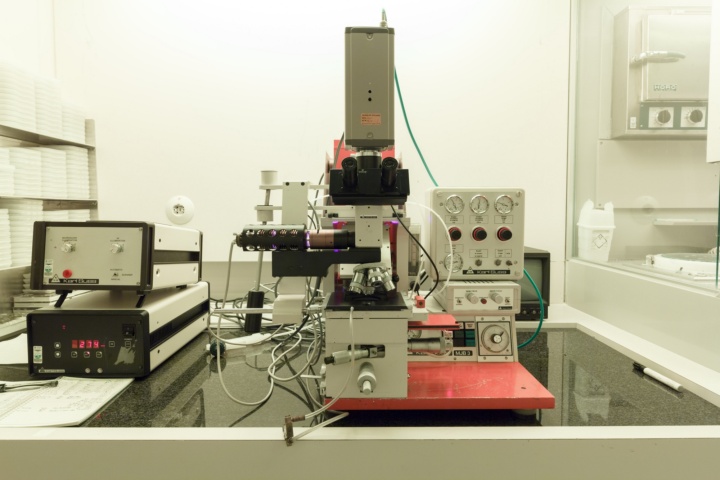

Lithography

Positive and negative tone processes available, acceleration voltage up to 30kV, resolution 10nm, laser interferometer stage, stitching and overlay (30nm, mean+3s), high resolution-low current and low resolution-large current modes, electron beam induced deposition (EBID), fixed beam moving stage, nanomanipulators.

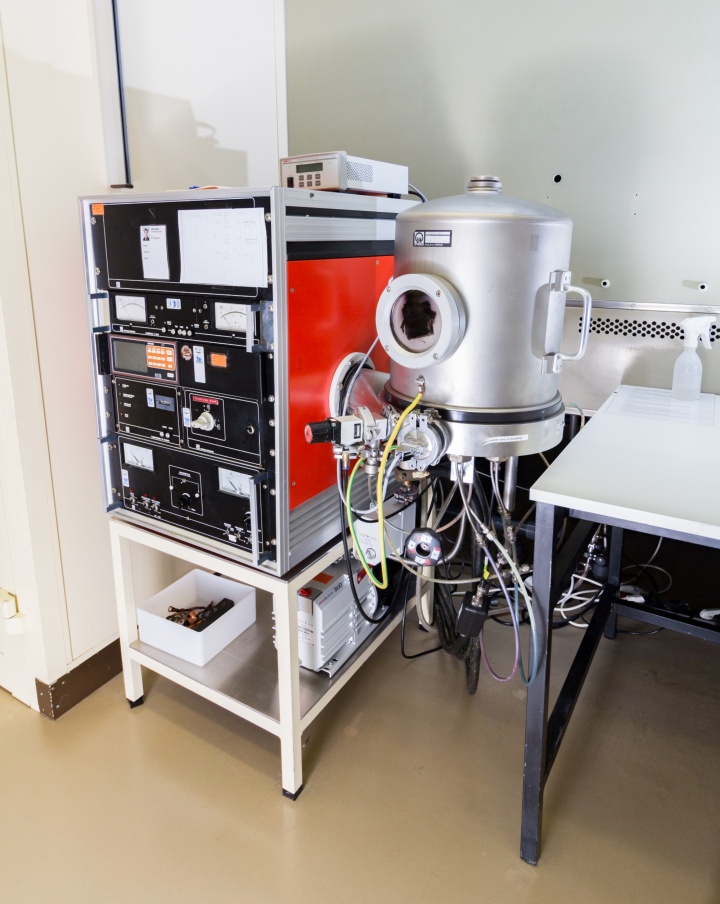

Thin Film deposition

Thermal evaporator with three sources, samples sizes > 4’’ possible.

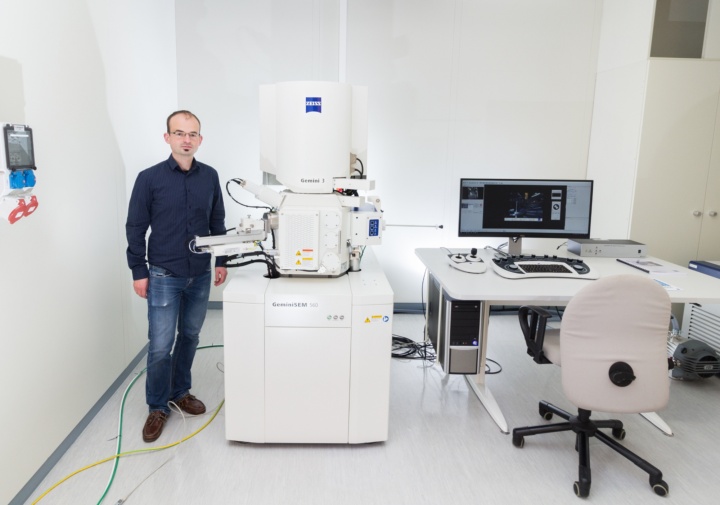

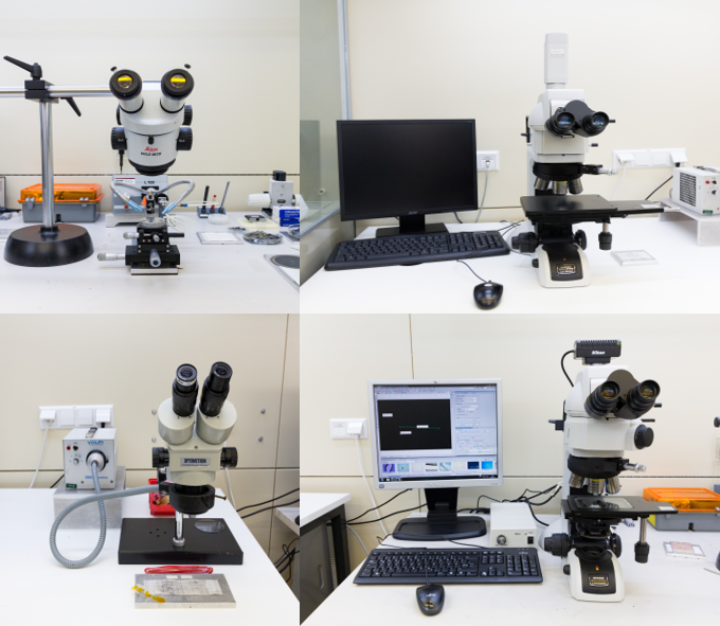

Microscopy

Dry Etching

Available gases BCl3, SiCl4, Cl2, CH4, H2, CHF3, SF6, O2, Ar, He, N2

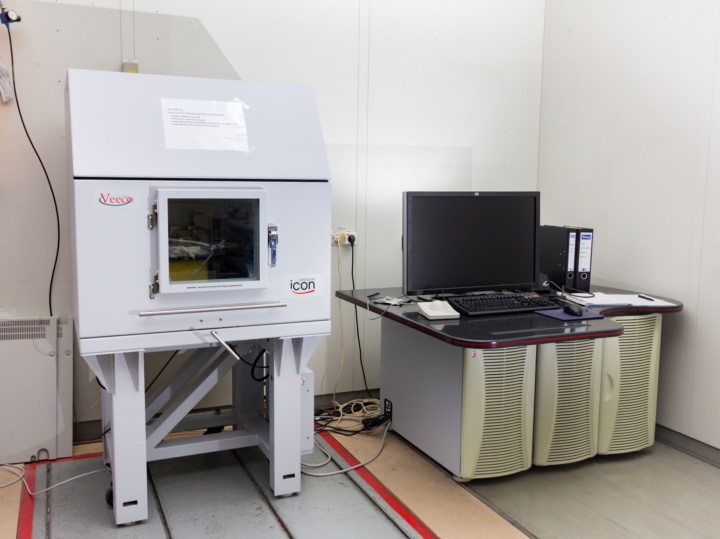

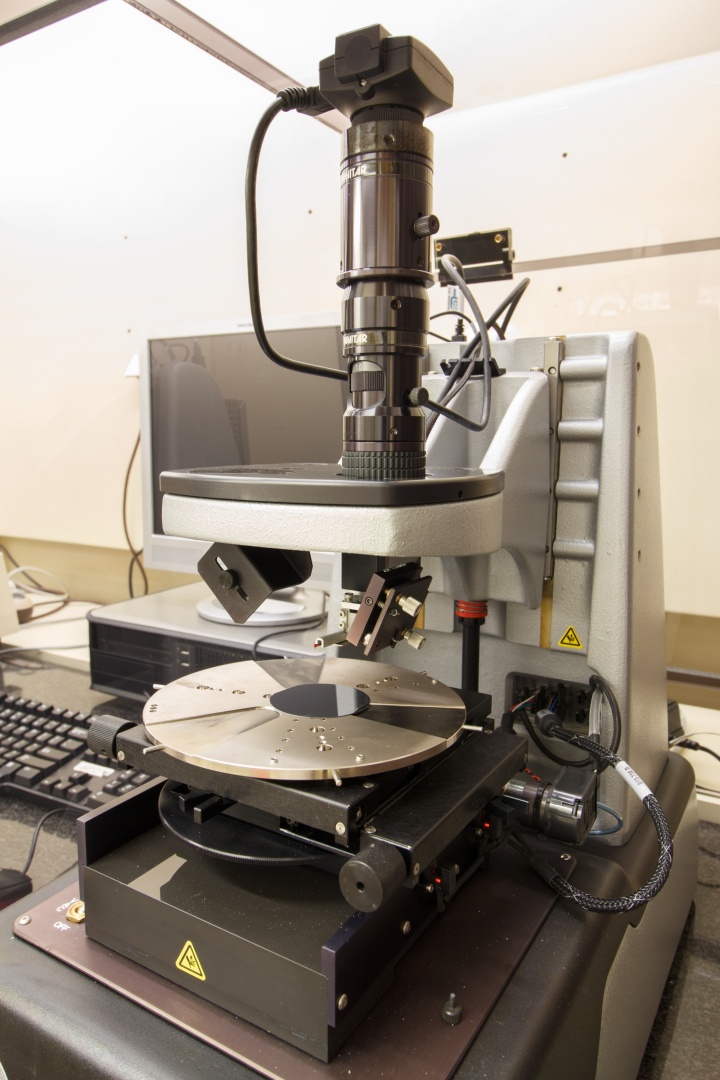

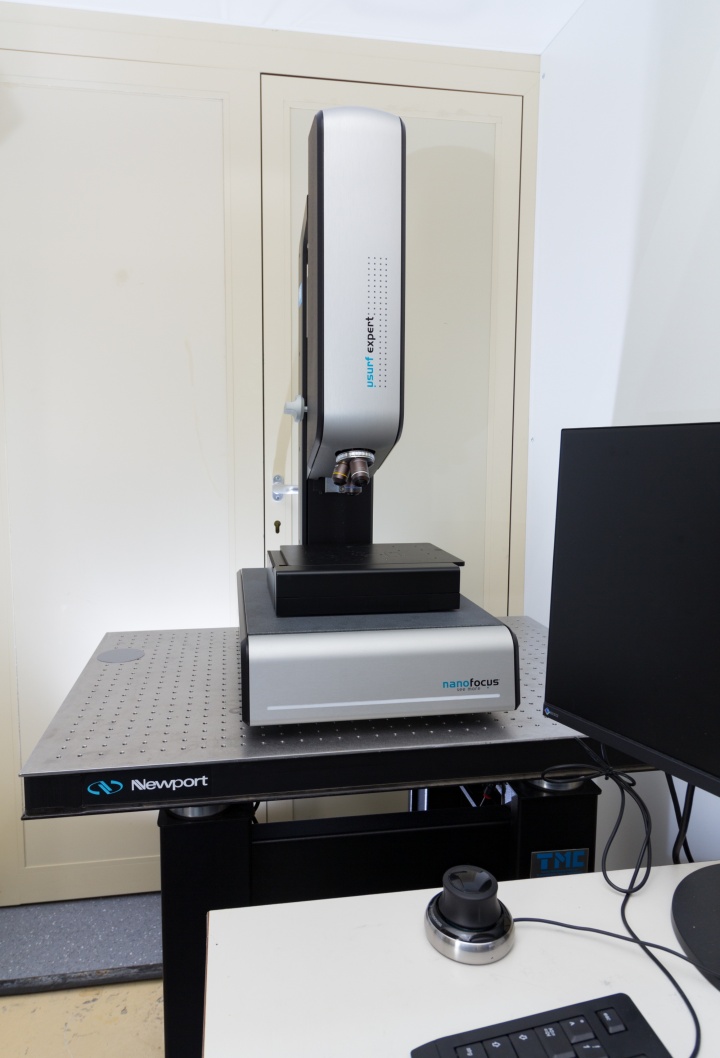

Profilometry

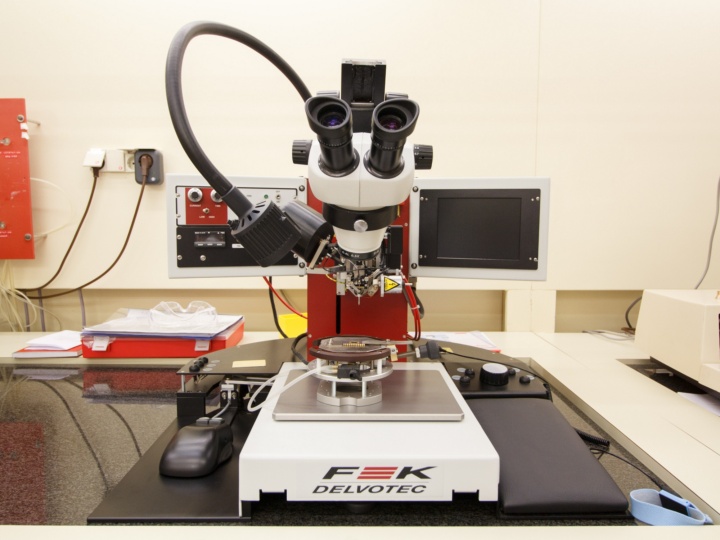

Wire Bonding

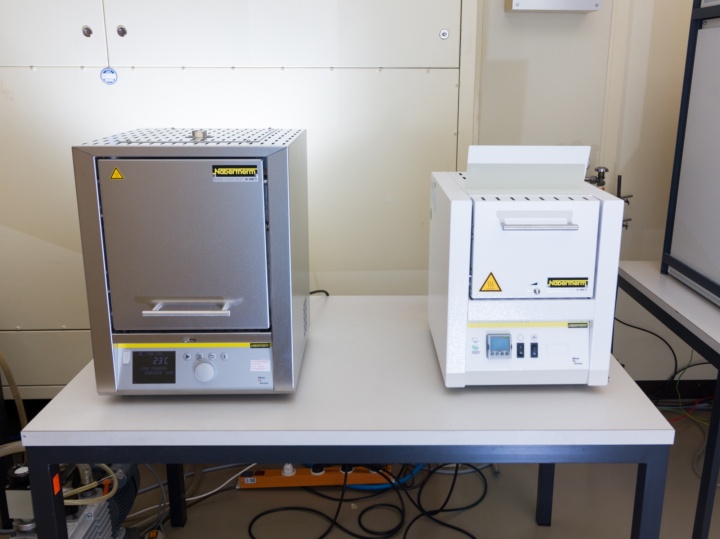

Miscellaneous

Controlled environment (vacuum, gases), up to 500°C.